![]()

NKZ Nitriding Potential Simulator

|

|

FEATURES

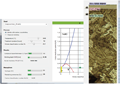

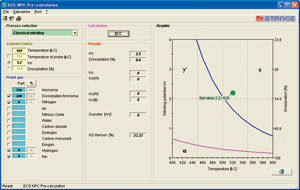

NkZ software module is a software run in Windows PC.It calculates heat treating parameters, such as nitriding potential, hydrogen content etc., from input conditions of method of heat treatment and gas composition. The result is shown on a phase diagram, such as Lehler or Kunze dependent on the method of heat treat you selected. With this off-line use, you can manipulate heat treatment parameters as much as you want until optimization is achieved. Once you get the value, the parameters can be planted into actual controller or system at site.

Due to derivation based on theoretical calculations, this software does not provide you with exact number guarantees what you expect. on the treatment, but with closest figures what we can get from most advanced technology and knowledge. With this, you can eliminate drastically number of try and error actions before you get treatment you expected.

With intranet connection to any of Stange SE6XX controllers on local control panels, the actual condition underway is also overwritten on the phase diagram where result of a calculation is shown on. This online usage enables you to know what the process going on directly from metallurgy and what you desire on the treatment. Should any irregular circumstances

are recognized, you can update the new control parameters derived form this software in order to revive the process. Derived control parameters to be updated in the controller can be transferred through the intra-net communication network.

NKZ software used together with Stange NHT case depth calculation software gives you a set of control set-points, such as heat treatment time and nitriding, oxygen and carburizing potential.

Features:

- Selectable method of heat treatments, gas nitriding, gas nitro-carburizing, gas oxinitriding, pre-oxidization and post-oxidization

- Verification of control and facility parameters, such as KN, temperature, nitriding time, gas mixture, etc.

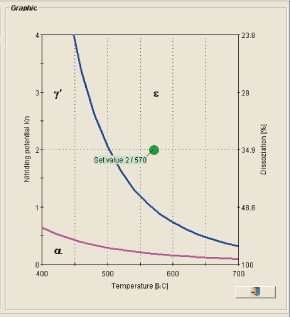

- Graphical display of calculated value on metallurgical phase diagrams, if it is off-line calculation mode.

- Graphical display of calculated value and actual value on metallurgical phase diagrams if it is on-line calculation mode.

- A data set for comparisons with other heat treatments, such as X-nitriding.

SPECIFICATION

【INPUTS/SELECTION】

- METHODS of HEAT TREATMENTS

Nitrocarburizing、Classical Nitriding、Oxynitriding、X-Nitriding、Pre- Oxidation、Post-Oxidation

- SETPOINTS and PARAMETERS for CONTROL

Temnperature、Temperature of Probe ℃、Nitriding potential(Kn)、 Dissociation %

- GAS COMPOSITION

Ammonia、Dissociated Ammonia、Nitrogen、Air、Nitricoxide、 Carbon Dioxide、Endogas、Carbon Monoxide、Exogass、Hydrogen

【HOW TO USE】

- Inputs all conditions and set-points

NOTE: Parameters and set-points to be input may vary with which method you selected.

- Push "Calculation" button

Calculation is updated with the new data.

【RESULT of CALCULATION】

- In tabulate form

Nitriding Potential(Kn)、Dissociation %、Oxidation potential(Ko)、Carbon potential(Kc(W))、Carbon potential(Kc(B))、Oxygen sensor EMF(mV)、 Hydrogen sensor( %)

- In graphical expression

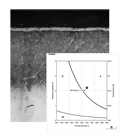

Result is marked in Lehler diagram on nitriding process and in Kunze diagram on nitro-arburizing

process. If it is used in on-line mode, another marker appears too to show actual value underway in a furnace.

| Lehler Phase Diagram (Example of Off-line mode) |

Kunze Phase Diagram (Example of Off-line mode |

|

|

※For:Southeast Aisia East Aisia & Oceania Regions