![]()

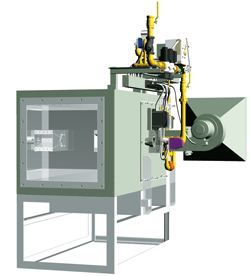

YHP-2

Hybrid placer (advanced flip chip & die bonder)

|

FEATURES

- Capable of mixed mounting of SMD components and semi-conductor components

- Capable of handling multiple types of the dipping unit

- Usable for dipping &stamping by the dipping unit

- Applicable for a wide area up to L300mm x W200mm

Technical Data

| PCB dimensions | L300xW200mm(Max)~L30xW30mm(Min) | |

| PCB thickness | 0.1mm~3.0mm | |

| PCB transport diredion | Right→left(option;left→right) | |

| Conveyor reference | Front side(option:rear side) | |

| Mounting accuracy | F type | Absolute accuracy (μ+3σ):±20μm |

| 4M type | Absolute accuracy (μ+3σ):±30μm |

|

| Load control | F type | Load control range;1 to 49N Load control accuracy;1 to 9.8N:±10% Load control accuracy;9.8 to 49N:±5% |

| 4M type | Load control range;2 to 10N Load control accuracy;±20% |

|

| Mounting/dispensing cycle time (Under optimum conditions) *Procee time not included |

4M type | 0.5sec/CHIP(When continuos pickup at work) |

| FF type | 0.8se/CHIP(Tape reel and tray supply case) 1.3sec/CHIP(Wafer supply case) | |

| FD type | As the measure as vary depending on the operation, please consult separately. | |

| No. of componebt types (Max, for 8mm tape conversion) |

When using the front side 8 in-line plate (in front of the conveyor installation position) |

36 types(8+8+20), 28 types(8+20),16 types(8+8) or 8 types(8×1) *The number of type is reduced depending on equipment of the supply system and supplementary system. |

| When using the front side 20 in-line plate (in front of the conveyor installation position) |

40 types(20+20) or 20 types (20 x1) *The number of type is reduced depending on equipment of the supply system and supplementary system. |

|

| Component supply configuration | ●Tape reel ●Bulk ●2,4inch waffle tray (Equipped with an auto-changer) ●6,8inch wafer (Capable of handling expanded wafer and simple expanding, placing with face-up and face down) |

|

| Component applicable for mounting | 0402~□15mm component (*1:As a special nozzle and a special feeder are required, please consult separately) SOP,SOJ,QFP,connector, PLCC,CSP,BGA,PGA,Flipchip,Barechip,Wafer-level CSP, Other special components(Please consult separately.) |

|

| Power supply | 3-phase AC200/208/220ノ240/380/400/416V±10% 50/60Hz | |

| Rating | 4.4kVA | |

| Average power consumrtion *When running Yamaha's standard operations |

0.7kW | |

| Air supply source | 0.55Mpa or more, 300l/min.(ANR)(Max), in clean, dry state | |

| External dimensions | L1,350xW1,408xH1,850mm | |

| Weight | Approx. 1,450kg | |